Textiles goes circular”- Coverage of Circular Apparel Innovation Factory (CAIF) in Business India, July 2024 Issue

New Delhi, 18th July, 2024– Venkat Kotamaraju, Partner and Director, Circular Apparel Innovation Factory (CAIF), Intellecap and CAIF’s overall effort to take the Industry to go circular was featured in Business India’s, July 2024 Issue.

In a freewheeling conversation with Arbind Gupta, Assistant Editor, Business India, Venkat highlights how, “CAIF has set itself an ambitious mission to build the ecosystem and capabilities to accelerate the transition to circularity – from the margins to the mainstream”.

Notably this is the third detailed story on CAIF by Business India who have been keenly following our transformative work across the years. The first story titled, ‘The Textile & Apparel sector looks to build capabilities to drive the transition to a circular economy’ was featured in Business India’s Nov 2021 Issue and the second one titled, “Textile Industry gets ready to go circular” was featured in the Business India’s Special Climate Edition, Nov 2022 Issue.

—

Getting Future Ready

Since India is one of the largest manufacturers of T&A (textiles and apparel) in the globe, it has now become paramount for it to have a right kind of textile recycling ecosystem in place to meet its SDG goals.

With sustainability and circularity becoming crucial aspects of responsible manufacturing of textiles and apparel, brands and manufacturers are now engaged in lot of conversion on how they can help their supply chain partners get decarbonised through energy efficiency, transition to renewable energy, water efficiency to save water, replacing chemical dyes and chemicals with more sustainable alternatives.

“The other side is where brands have specific commitments made publicly to become more circular, more engagement on how we can ensure more recycled material coming from the waste that can come to the manufacturing ecosystem,” says Venkat Kotamaraju, director, CAIF, Intellecap. “This means that, with more and more supply of recycled material starting to replace some component of virgin material, there is less demand and less extraction of virgin material going down and getting replaced with the recycled material. So, there is less getting extracted from the planet.”

“Apart from recycling materials and resources coming in to start replacing virgin material, there is also a greater amount of intent and conversations around how we create a value chain and the supply chain for alternative materials,” adds Kotamaraju. “Industry recognises that, if we need to move towards a more sustainable future, apart from bringing the recycled material, there needs to be clear action towards creating a demand and supply for alternative materials (for example, banana or pineapple waste fibre, etc), as they are less resource- and carbon-intensive”.

Circular Apparel Innovation Factory (CAIF) is an industry-led platform, the mission of which is to build the ecosystem and strengthen capabilities to drive the transition to a circular economy in the apparel and textile industry. The platform is building the textile industry’s innovation infrastructure by bringing together key stakeholders to collaborate and work together on achieving the five key circular goals. CAIF is a global initiative of Intellecap, an impact advisory arm of the Mumbai-headquartered Aavishkaar group, a leading impact investing organisation, which works to build businesses that can benefit the underserved segments across Asia and Africa.

CAIF initiatives

Founded in 2018, CAIF is supported by the DOEN Foundation (a Dutch organisation encouraging initiatives in the field of culture and cohesion, as also green and inclusive economy) and Aditya Birla Fashion & Retail Ltd (ABFRL), as its founding anchor partners. To accelerate the shift of the industry from its current ‘take-make-dispose’ approach to one that is more circular across the lifecycle, CAIF works with a diverse group of stakeholders from across the value chain.

Over the last six years, CAIF has been actively working with many Indian and global brands (H&M, Target Corp, SHAHI Exports, House of Anita Dongre, Trident, CL Gupta, Raj Group, Jay Jay Mills and CTA Apparels), through different pilots and initiatives. It has identified and mapped multiple innovators across different dimensions of circular economy relevant to the textile and fashion industry.

“CAIF is an industry-led and industry-facing platform born with a singular purpose of helping build a planet and people positive textiles and apparel industry. In line with this purpose, CAIF has set for itself an ambitious mission to build the ecosystem and capabilities to accelerate the transition towards circularity – from the margins to the mainstream,” explains Kotamaraju.

“We have a long way to go, but we are beginning to see light at the end of the tunnel” – Venkat Kotamaraju, Director, CAIF, Intellecap

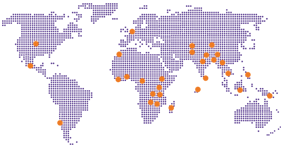

“Much of its thinking and work focusses on building ecosystems and capabilities that help decarbonise the industry, get to zero-leakage of textiles waste into the environment, stop leakage of single-use plastics into the environment and securing a thriving future for the millions of workers employed across the textiles and apparel value chain through creation of green and circular jobs at scale,” he adds. “CAIF is designing and shaping work in the key global south economies incl. South Asia, SE Asia and East Africa, which play a critical role in the complex global value chain”.

ACRE and more

Back in 2020, CAIF conceptualised and designed the ACRE Program (Accelerating Circular and Regenerative Economy), with specific sub-programs, each with the intent to develop proven and viable pathways to circulate, regenerate and eliminate waste/harmful materials from the fashion/textiles and apparel value chains.

Since late 2021, it has operationalised the Closing The Loop (CTL) program as part of the circulate pillar. CTL envisions an integrated circular textiles waste model (CTWM) with a pan-India network of hyper-local material recovery facilities which are powered by waste pickers. It is not just recovering and recovering value from textiles/apparel waste at scale, but also unlocking green and circular jobs and improving the livelihoods of the informal, marginalised and underserved individuals and communities across the waste ecosystem.

Starting with two micro-entrepreneurs across two pilot cities in late 2021, the CTWM model now spans nine cities, has already diverted half a million kg (~500,000 kg) of textiles (collected and sorted) waste and in the process engages 350 waste workers, trained almost 700 waste workers (of which 90 per cent are women) in market-informed skills of sorting and segregating.

In partnership with seven grassroots organisations (so far), CAIF has enabled 18 micro-entrepreneurs across nine cities and the waste workers are seeing an average increase of 15-20 per cent in their incomes. More so, with the micro-entrepreneurs now engaged in commercial contracts with some leading recyclers, it is working closely with select brands and their manufacturers on their material transition journeys. Pace and scale is a key driver for it and for that, in the current phase it is mobilising capital, knowledge, networks and technologies (solutions) to create value for all stakeholders involved.

Building on this early success, CAIF is now being engaged by brands in establishing reverse logistics for materials which is key to achieving their circularity and net-zero ambitions.

“For us intent is prime,” affirms Kotamaraju. “We conceptualised the ACRE program and Closing the Loop program (within the broader ACRE) through a bottom-up approach and built it around the waste pickers and their communities, who, despite their contributions to waste management, have been caught in intergenerational poverty. A key design principle (emerging out of a study we had commissioned back in 2019-20) was that the solution to the scale and complexity of the waste problem needed a rather hyper-local solution and the best way to enable that was through the existing waste workers and the civil society organisations. Kudos to every member of the CAIF team, who remains committed and passionate to find a resolution to this existential challenge. We have a long way to go, but we are beginning to see light at the end of the tunnel”

Handling & recycling of pre-consumer and post-consumer textiles wastes is critical

ACEing the agenda

In 2021, CAIF launched Project ACE with the singular aim of a business case for low carbon/circular solutions in India. During the first phase of ACE (2021-23), ACE was designed to address two clear ecosystem gaps which are key to accelerate the decarbonisation of textiles and apparel supply chain in India: lack of awareness on the business opportunity from adopting circular economy/low-carbon solutions and a limited awareness about and access to circular/low-carbon solutions that can address emissions across the supply chain.

To create a robust business case, CAIF designed demonstration pilots with multiple stakeholders (brands and their manufacturing partners) to test, validate and commercially deploy high potential low-carbon solutions in areas including energy efficiency, water efficiency, alternative dyes and chemicals, digital solutions in textiles waste traceability, etc. H&M, Target Corp, SHAHI Exports, House of Anita Dongre, Trident, CL Gupta, Raj Group, Jay Jay Mills, CTA Apparels and their manufacturing partners are some of the brands that participated.

Some of the key outcomes it was able to engineer during the Phase 1 (2021-23) included 15 per cent improvement in energy efficiency, 25 per cent reduction in process heat, 35-40 per cent reduction in waste-water generation and an overall cost savings of about 20 per cent for the participating manufacturers.

According to brands and textile manufacturers, three key components of ACE were critical in design/execution of the pilots along with expediting the buy-in from leadership/board teams for eventual long-term commercial contracts: the ability of CAIF to source and evaluate high-potential innovative solutions; technical assistance provided by CAIF to innovators (from problem-solution through product-market fit) and the capacity building support provided to manufacturers and supply chain partners; and designing a financial assistance through a pool of capital available for both innovators and manufacturers to execute the demonstration pilots and develop a proof of concept.

India and abroad

Earlier, CAIF was focussed on India, as the country offered a significant opportunity to be a large manufacturing hub for the global textile value chain and has a large consumption base. India was the largest importer of second waste. In the last few years, CAIF has increased its focus from India to other markets, including Bangladesh, where it launched a programme, where they are checking the quality while mapping the environmental and social sustainability hotspots across the readymade garment manufacturing value chain in Bangladesh.

Through this initiative, Oporajita (in collaboration with H&M Foundation), in Bangladesh, multiple partners are joining hands to equip women garment workers for a future defined by automation and digitalisation. As one of the partners in this collective impact initiative, CAIF is creating sustainable livelihood opportunities for out-of-work RMG workers through identifying and developing capacity on circular jobs and circular micro-entrepreneurship models. It is building capacities of both the out-of-work women garment workers and SMEs in the garment manufacturing and allied sectors. Over the past two years, it has engaged with over 50 SMEs in Bangladesh, trained around 1,250 out-of-work women garment workers, of which 650 have been employed back in the sector and seen their incomes improve by 8 -15 per cent as a result of the capacity building efforts.

Meanwhile, the handling and recycling of pre-consumer and post-consumer textiles wastes is turning out to be a critical component of the entire process of circularity. More so, since India is one of the largest manufacturers of T&A (textiles and apparel) in the globe, it has now become paramount for it to have a right kind of textile recycling ecosystem in place to meet its SDG goals.

Textile Powerhouse

India is poised to become one of the most important textile recycling hubs of the world. While India has been a powerhouse in textile manufacturing, only recently, textile recycling has gained prominence. In recent years, large scale infrastructure set-up for sorting, processing and recycling has received attention in the call for scaling textile recycling worldwide. Towards building up capacity and putting up a much-needed ecosystem for recycling, India today hosts large sorting and grading facilities at the SEZ of Kandla in Gujarat, employing over 3,000 workers.

Besides, in Panipat, Haryana, India also houses one of the largest industrial clusters for mechanical recycling in the world. There are estimated between 900 and 2,500 sorting, recycling and spinning units. The Panipat cluster employs about 4 million informal workers, who are engaged in processing textile wastes.

In Tirupur in south India, a knitwear hub has also been growing into an efficient cluster for recycling, with focus on pre-consumer waste. Amroha, in Uttar Pradesh, is largely working with the cycling of textiles, where discarded inputs are recycled and repurposed into something of lower value. Pre-consumer textile waste consists mostly of post-industrial waste from textile factories, while post-consumer comes from used garments and household textiles.

Experts view that recycling solutions and innovations have to be hyper local in order to be sustainable in a true sense. Earlier, while most of the wastes were produced within the country, the recycling solutions were primarily available outside India. Towards this end, clusters like Kandla, Panipat and others can play a big role.

Out of the over 7,800 tonnes of textile waste handled annually in India, an estimated 51 per cent is post-consumer waste, originating from local consumers. Another 42 per cent is pre-consumer wastes. Seven per cent is imported waste.

“India is becoming a major recycling hub with multi-stakeholder investment projects, run by Fashion for Good and Reverse Resources with giant textile players like Arvind, Wellspun India and Birla Cellulose taking the lead and supported by international players like PVH, Adidas, Tesco, Target, Levi’s. This opens up opportunities for developing novel value chains and business models for valorising textile waste inter-continentally. Additionally, with growing purchasing power India is also a major producer of post-consumer textile waste domestically,” states a white paper jointly prepared by The Swedish School of Textiles, IIT Delhi and Wazir Advisors.