People and planet positive: How an inclusive circular textile waste management model is improving livelihoods of waste pickers in Bengaluru and saving the environment

An award winning and recognised social entrepreneur in her own right, Indumathi is an expert in waste management and all its processes. She has not only successfully demonstrated to the city of Bengaluru that waste pickers can become waste entrepreneurs but also advocated for recognising the role of the community in mitigating the effects of climate change and saving the environment from the unending waste supply through circularity.

But the textile waste brought in as part of the dry waste collection drives sat in a corner. A significant amount of textile waste passed through her centres with no sustainable solution, often ending up in landfills. This troubled her, as sending materials to the landfill neither made a good decision business or environment wise.

India, one of the world’s largest exporters of textiles and apparel products, faces a significant challenge in managing textile waste. Despite the country’s manufacturing base and famous recycling prowess vis a vis textile waste, it lacks a formal infrastructure to properly address the issue. And therefore, textile waste is the third largest source of municipal solid waste in India, the potential to provide income and stable livelihoods for workers lying untapped.

Indumathi’s story highlights the pressing need for innovative solutions in the textile waste sector, one that could potentially replicate the recycling success story of the PET single use bottles in the country (India recycles more than 80% of PET bottles) while opening up avenues for green jobs in the sector.

‘Closing the Loop on Textile Waste’

The opportunity to address the mounds of textile waste came Indumathi’s way in early 2023 when she joined Circular Apparel Innovation Factory’s (CAIF) ‘Closing the Loop on Textile Waste’ program under the Saamuhika Shakti initiative in Bengaluru.

Through the program, Indumathi and her team learnt how to process textile waste and create an additional business line out of it from her Dry Waste Collection Center (DWCC), and join the cohort of the many DWCC operators in Bengaluru who have embarked on a similar journey as textile waste entrepreneurs of Saamuhika Shakti.

Indumathi and other waste workers sorting textile waste at DWCC. | PC: Circular Apparel Innovation Factory (CAIF)

Circular Apparel Innovation Factory (CAIF), an Intellecap initiative dedicated to helping build a planet positive (resource efficiency through decarbonization and zero waste to environment) and people positive (creating sustainable green livelihoods) textile industry through adoption of circular economy, became a partner of the Saamuhika Shakti initiative in early 2023 with the objective to:

– Establish an integrated Circular Textile Waste Management (CTWM) model in Bengaluru to recover and reclaim value from textile waste;

– While creating green and sustained livelihoods for the underserved waste picker community.

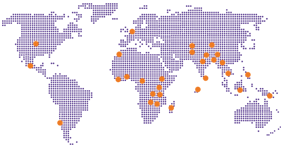

This CTWM model is part of CAIF’s larger ‘Closing the Loop on Textile Waste’ program, being implemented in 10 other cities across India. The Bengaluru implementation is supported by H&M Foundation and Saamuhika Shakti.-

In 2023, eight DWCC operators (of which three are women) in Bengaluru successfully adopted and integrated the CTWM model into their existing dry waste businesses. CAIF along with on-ground implementation partner Hasiru Dala, built the capacities and capabilities of the eight DWCC operators and waste pickers on:

– How to collect post-consumer textile waste from communities

– Conduct market focused sorting and establish a textile waste business.

The CAIF team also supported the DWCCs establish market linkages with buyers of textile waste such as resellers, up-cyclers, key textile recyclers in Panipat (which is one of the two major textile recycling hubs in India), and downcyclers resulting in regular transactions between CTWM waste entrepreneurs and such buyers.

This was critical for closing-the-loop on textile waste by reintroducing recycled materials back into the textiles and apparel and other supply chains.

Kumuda is the manager of a DWCC where textile waste is processed. | PC: Vinod Sebastian/Saamuhika Shakti

By the end of Saamuhika Shakti’s Phase 1 in December 2023, in just 11 months, CAIF’s intervention helped divert 131,436 kg of post-consumer textile waste from going to landfill and impacted the lives and livelihoods of 225 waste pickers through capacity building support. Of these, 33 waste pickers were directly engaged in handling textile waste (green jobs) at the DWCCs and experienced an increase in incomes ranging between 18% to 25%.

Training on market focused sorting of textile waste at Dry Waste Collection Center (DWCC). | PC: Circular Apparel Innovation Factory (CAIF)

Setting up the first of its kind Textile Recovery Facility (TRF)

As the ‘Closing the Loop on Textile Waste’ program matured, it became evident that for scaling the model, aggregation and recovery of textile waste in the city will be critical to guarantee volumes and to meet market requirements. The focus therefore needed to shift to enabling waste entrepreneurs to access textile waste at an aggregation centre that would not only efficiently cater to the diverse buyer requirements but also unlock more green jobs and elevated job roles for the waste picker communities in Bengaluru. In fact, the CAIF team had factored in this critical learning from Bengaluru while designing the replication of the CTWM model across other cities in India.

The design of CAIF’s intervention for Saamuhika Shakti’s Phase 2, launched in January 2024, envisioned a hub and spoke model wherein a total of 16 DWCCs will operate as spokes for collection and primary sorting of textile waste and a Textile Recovery Facility (TRF) established and operated by one or more waste entrepreneurs will function as the city-level hub for secondary sorting and value addition of textile waste.

The TRF is conceptualised as one of the biggest buyers of textile waste for the DWCCs solving the dual challenge of lack of space at the DWCC level and barriers to regular cash flows for DWCCs.

The hub and spoke model involves 16 Dry Waste Collection Centers (DWCCs) acting as spokes for the collection and primary sorting of textile waste. These spokes feed into a central Textile Recovery Facility (TRF), which serves as the city-level hub. | Illustration: Circular Apparel Innovation Factory (CAIF)

The hub and spoke model involves 16 Dry Waste Collection Centers (DWCCs) acting as spokes for the collection and primary sorting of textile waste. These spokes feed into a central Textile Recovery Facility (TRF), which serves as the city-level hub. | Illustration: Circular Apparel Innovation Factory (CAIF)

In Phase 2, CAIF has set an ambitious target of diverting 800,000 kg of textile waste over three years (2024-2026) and positively impacting the lives and livelihoods of 500 waste pickers in Bengaluru.

Today, the vision of the hub and spoke model is a reality with the inauguration of the first Textile Recovery Facility (TRF) in August 2024. Indumathi, whom we introduced earlier, has taken on the responsibility of setting up and managing the TRF, in addition to running her existing DWCCs.

The Textile Recovery Facility (TRF), | PC: Circular Apparel Innovation Factory (CAIF)

Market focused sorting being done at TRF; and colour sorted textile waste kept separately at TRF. | PC: Circular Apparel Innovation Factory (CAIF)

The TRF has the capacity to process 50 MT of textile waste per month.

The CTWM model being piloted in Bengaluru demonstrates that through the circularity journey we can sustainably address the many challenges of climate and the environment and it need not be at the cost of overlooking the marginalised communities who form the bedrock of the efforts. We can be both planet and people positive.